Xerox

Crown Gear

Designed gear teeth with crown to prevent edge contact of mating gear teeth when subject to shaft misalignment.

What is Circular Lead Crowning?

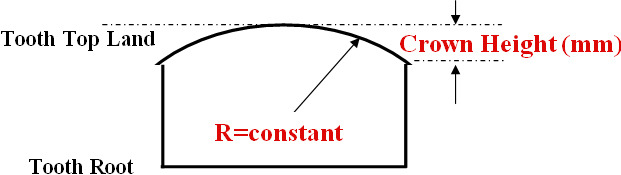

Circular Lead Crowning is the rounded surface contour of each tooth along a gear’s axial direction of rotation (fig. 1.1). Surface contour is defined when a constant radius has a crown height specification at each face of XX mm.

Figure 1.1 - Isometric View of Single Tooth

Figure 2.1 - Front View of Single Tooth

Motivation for “Circular Lead Crowning”

- To prevent edge contact of mating gear teeth when subject to shaft misalignment. Edge contact of mating teeth generates tooth noise vibration, known as “transmission error” (TE).

- To reduce contact stress of mating teeth when subject to shaft misalignment. This is accomplished by forcing contact back towards the center of the mesh interface.